| |

Polarity.

The connector is connected to the negative and the workpiece to the positive pole . A reverse polarity has been shown effective for certain metals , such as for aluminum ( and alloys ) and brass .

Welding current .

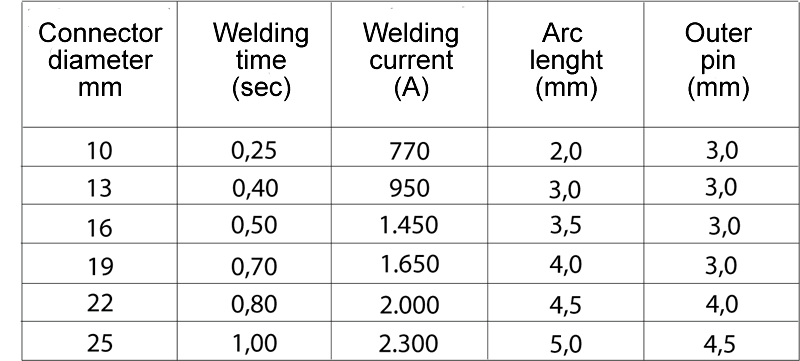

Connector according to the measures , the welding current is between 300 A and 3,000 A approximately.

For the welding of steel connectors , not alloyed by arc melting and forging, with ceramic ferrule or shielding gas , the correct current intensity can be assessed mainly by the two following formulas:

I (A ) = 80 xd ( mm) - for connectors with diameter 16 mm approx.

I (A ) = 90 xd (mm ) - for connectors with diameters greater than 16 mm.

For an alloy steel, usually choose a lower current by 10 % approx.

Arc voltage

Is mainly determined by the height of elevation and the welding current .Generally used values between 20 V and 40 V. With respect to a normal state of the surface , impurities such as oil or grease, the arc voltage increases , and the use of an inert protective gas reduces the arc voltage.

Welding time

Basically can be estimated by the two following formulas:

tw (A ) = 0.02 xd (mm ) - for connectors with 12 mm diameter up to approx.

tw (A ) = 0.04 xd (mm ) - for connectors with diameters greater than 12 mm.

The values shown apply to the welding position PA. The welding time should be reduced for positional welding PC

Elevation

The elevation is between 1.5 mm and 7 mm approximately, and is proportional to the diameter of the connector.

Connectors for welding on coated surfaces , the height of elevation must be higher than is chosen to uncoated surfaces . A higher elevation arc length increases , and therefore the arc voltage . Similarly , the risks of magnetic arc blow .

Protrusion.

Is generally between 1 mm and 8 mm, and is proportional to the diameter of the connector. Depends on the shape of the welding neck, the shape of the connector end , and ( for welding with ceramic ferrule ) of the internal configuration of the splint.

Sinking speed .

The sinking velocity should be between about 200 mm / s for connectors with diameters up to 13 mm and 100 mm / s for thicker connectors , in order to prevent molten metal projections . The sinking speed is proportional to the protrusion , in the case of mobile devices without shock.

- Welding variables , for welding of connectors by arc ,melting and forging, with ceramic ferrule or shielding gas.

- Polarity

- Arc voltage

- Welding current

-Welding time

- Elevation

- Protrusion

- Collapse speed

- Number and position of taking the mass |

|